Why do mineral source fulvic acid and biochemical fulvic acid both have the word “fulvic acid”, but their prefixes are different: mineral and biochemical? So today Jingfeng Humic Acid will conduct an in-depth analysis of this issue and dialectically analyze it from multiple angles. Let everyone be able to distinguish the good from the bad in the market in the future.

Different colors

Please look at the following pictures, do you feel familiar?

The yellow one on the left is biochemical fulvic acid, which is more common in the market. The black one on the right is mineral source fulvic acid, which is available in powder, tablets, granules, etc. on the market.

Different sources

Why must mineral fulvic acid be black, not yellow? Although mineral fulvic acid is humic acid, its raw materials are mainly peat, lignite, and weathered coal, so its appearance must be black.

- Peat is protected by the state, has too high a moisture content, and has too high a production cost. Therefore, although it contains a very high content of humic acid, it is almost not used as a raw material for mineral humic acid;

- Lignite is currently a good enough raw material for producing mineral potassium humate, and the mineral potassium humate it produces is also called primary humic acid;

- Weathered coal is lignite that has undergone a long period of change to form bituminous coal or anthracite. Bituminous coal and anthracite are formed after weathering. In this process, weathered coal belongs to regenerated humic acid.

- The raw materials of biochemical humic acid are: straw, sugarcane residue, and sawdust. According to its source, the colors of all biochemical humic acid are mainly yellow-brown, dark brown, and brown.

Different extraction methods

A. Extraction method of potassium humate from mineral sources

Extraction method 1 of potassium humate from mineral sources:

Alkali extraction method, 80%-90% of manufacturers are using it, so its finished products are all mineral humates, such as: potassium humate from mineral sources, sodium humate from mineral sources, potassium humate from mineral sources, etc.

The specific process is: mineral raw materials → oxidation activation → high-speed crushing → alkali extraction → acid precipitation → differential centrifugal separation → potassium humate from mineral sources (finished humus fertilizer).

Why should it be screened by differential centrifugal separation in this process? There are two reasons,

- First: Because its raw materials come from coal, it must be mixed with impurities such as soil and ore, which requires differential centrifugation to filter out impurities;

- Second: Potassium humate from mineral sources is a mineral humic acid with strong activity and relatively small molecular weight. This method is conducive to throwing out the materials we need and making finished products.

Extraction method 2 of fulvic acid from mineral sources:

Holographic cracking extraction method, this process is very rare. The extraction process is: mineral raw materials → high-speed crushing → constant temperature differential speed → weak current awakening → adding N/P/K → constant temperature differential speed → mineral fulvic acid (finished humic fertilizer). The whole process does not have too many chemical reactions, and it is basically a physical extraction.

There are two states of this process:

- The first is to form medium-micro particles after drying, and its humic acid content is higher, including its water solubility, anti-flocculation, and relatively better compounding properties;

- The second is to form a humic acid liquid suspension, and its active ingredients are suspended in the liquid. This process avoids the stratification phenomenon that occurs after the liquid fertilizer is left for too long.

The experiment was conducted on site to observe the water solubility of hollow microparticles of potassium humate obtained by holographic pyrolysis extraction. Since it is a hollow microparticle, it is vortex-shaped after being poured into water and completely dissolved in water in 30 seconds.

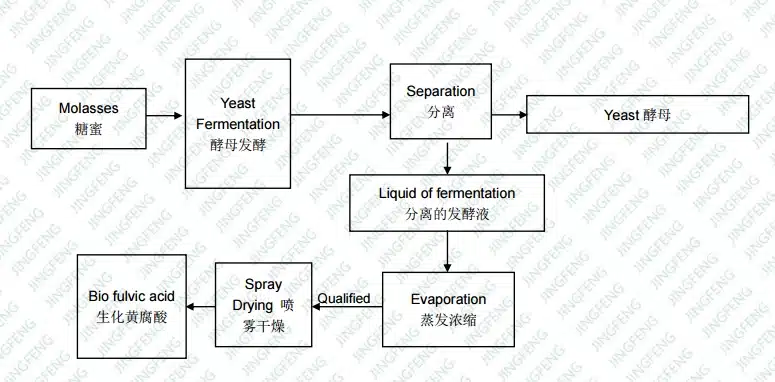

B. Extraction method of biochemical fulvic acid

Summary:

- There are two main ways to extract fulvic acid from mineral sources. Alkaline extraction is the most commonly used method, which can extract mineral fulvic acid, ammonium humate , potassium humate, sodium humate , etc.;

- The extraction of biochemical fulvic acid requires the addition of bacterial agents for fermentation, and then filtering to form residues to make bacterial fertilizer or organic fertilizer. The supernatant is directly used as liquid fertilizer, and then dried to form fulvic acid powder.

Different ingredients

The main ingredients of the two substances are as follows:

Mineral fulvic acid: Phenolic acids, fatty acids, benzene polycarboxylic acids.

Biochemical fulvic acid: Cellulose, hemicellulose, lignin, alcohols, proteins, sugars, phenolic acids, fatty acids.

Phenolic acid, fatty acid, and benzene polycarboxylic acid are all macromolecular structures and are very stable. Therefore, mineral potassium humate will not expire.

The molecular weight of structures such as cellulose, hemicellulose, lignin, alcohols, proteins, sugars, phenolic acids, and fatty acids is relatively small, and it is extremely easy to denature. For example, proteins will decompose, polysaccharides or alcohols will denature, etc., so the structure of biochemical fulvic acid is relatively unstable.

Difference in smell

Mineral fulvic acid: no smell

Biochemical fulvic acid: sugary, smelly

Comparison of shortcomings

A. Mineral fulvic acid

① There is an anti-flocculation limit.

- At present, the conventional mineral potassium humate on the market has an anti-flocculation limit of 18-25 degrees hard water. The mineral potassium humate produced by Jingfeng Humic Acid has an anti-flocculation ability of about 35 degrees.

- Flocculation mainly refers to the complexation reaction with calcium ions and magnesium ions, and the resulting macromolecular structure is insoluble in water. Therefore, in the market promotion, it is recommended to do anti-flocculation test for mineral potassium humate, and it is recommended to dissolve it in water together with calcium nitrate, including in some current macro-element water-soluble fertilizers. If the aqueous solution can be kept for more than one day, it can be considered for purchase and use.

- In addition, if the compound fertilizer is not a chelating calcium, magnesium and copper ion, it is not recommended to compound it directly, and an anti-flocculation test is required before use. The best way is to dissolve and use them separately to avoid flocculation and blockage of drip irrigation or sprinkler irrigation.

② The price of mineral potassium humate is relatively high. The cost of its raw materials, including lignite weathering lignite, potassium hydroxide, etc., is at a very high price when transported to the production enterprise. In addition to the reaction, discarding impurities, drying, equipment loss, personnel costs, etc., the production cost of mineral potassium humate is generally high.

B. Biochemical humic acid

① It must be used in large quantities to be effective.

② It is easy to breed miscellaneous bacteria. It can be seen that its three production processes require the addition of bacterial agents for fermentation, and the strains are difficult to control. The sugar content is relatively high, and it is particularly easy to breed miscellaneous bacteria.

Difference in the recognition of the Ministry of Agriculture

- The Ministry of Agriculture’s standard for humic acid fertilizers clearly stipulates the content of mineral fulvic acid, and biochemical fulvic acid is excluded.

- The industry standard “Potassium Fulvic Acid” clarifies that potassium fulvic acid is divided into mineral fulvic acid acid and biochemical fulvic acid according to the source of raw materials.

- Biochemical potassium fulvic acid only has industry standards, not Ministry of Agriculture standards.

Difference in research degree

- Mineral fulvic acid: The research history is long. China has been studying it since the 1950s. The properties and components are more thoroughly understood, but the mystery has not been completely solved.

- Biochemical fulvic acid: The research time is short. my country has only started to develop since the heyday of the papermaking industry in the late 1980s. There are still many unsolved mysteries, and many key data and standards are relatively vague.

Comparison of elemental composition and functional groups

| C | H | N | S | O | H/C (average) | Total acid group | COOH | OHPh | |

| Biochemical fulvic acid | 45-47 | 7-8 | 4-5 | 1-2 | 39-41 | 1.84 | 5.8 | 3.3 | 2.5 |

| Mineral source fulvic acid | 48-50 | 3-4 | 1-2 | 0.5-1 | 41-43 | 0.89 | 10.0 | 8.1 | 2.8 |

- The main difference lies in the H/C ratio and functional groups. From the total acidic groups and the number of carboxyl groups, it can be seen that mineral humic acid is stronger.

- Both have high carbon content and high oxygen content;

- Acidic groups determine the number of active and active groups. The more acidic groups there are, the more active groups there are, and the more effective they are.

Functional characteristics difference

| soil improvement | Root growth | Enhance stress resistance | Increase production and improve quality | Improve fertilizer utilization | Number of complex functional groups | Improve soil organic carbon | |

| Biochemical fulvic acid | ★★★★★ | ★★★ | ★★★ | ★★★ | ★★★ | ★★★★★ | ★★ |

| Mineral source fulvic acid | ★★★ | ★★★ | ★ | ★★ | ★★ | ★★ | ★★★ |

Question and answer:

1. There is no brown or black difference between mineral humic acid, and brown fulvic acid refers to biochemical!

Answer: If you see brown fulvic acid on the market, it must be biochemical without a doubt.

2. What is the difference between biochemical fulvic acid and potassium fulvic acid?

Answer: There is not much difference. Generally, biochemical fulvic acid containing potassium oxide can become biochemical potassium fulvic acid.

3. Humic acid extracted from peat soil, what type of fulvic acid is it?

Answer: It belongs to peat, which is a raw material for extracting mineral potassium fulvic acid, and belongs to mineral humic acid.

4. What is the difference between mineral fulvic acid and mineral potassium fulvic acid?

Answer: Mineral potassium fulvic acid is formed by oxidative decomposition of mineral fulvic acid and alkaline extraction of potassium hydroxide.

5. What is the difference between biochemical humic acid and mineral humic acid?

Answer: Intuitive: color, taste; the depth of the difference is described above.

6. Is biochemical fulvic acid molasses powder, yellow powder, sugar residue?

Answer: It may be molasses powder, yellow powder, sugar residue, or it may be some other by-products such as papermaking and monosodium glutamate.

User selection suggestions:

- Choose products reasonably according to soil needs and crop growth period!

- The storage environment of biochemical humic acid products must be dry to avoid moisture absorption!

- During the dissolution of mineral potassium humate, pay attention to a small amount and multiple times, fully dissolve, and dilute it twice before use as needed! Because mineral potassium humate is highly concentrated, if the amount of water is small, it will not dissolve, affecting the use effect of the product.

- During the use of mineral potassium humate, try to avoid direct mixing with elements such as Ca, Mg, and Cu! Or do an anti-flocculation test before mixing.

- The application of mineral potassium humate should follow the principle of more than 2 times for vegetables and more than 3 times for fruit trees! The quick-acting property of mineral potassium humate is relatively weak, and its fertilizer effect is very long. After using it 2-3 times, its real effect can be reflected.

- When applying biochemical humic acid and mineral potassium humate to crops, they need to be used according to the product instructions. It is not recommended to add excessive amounts!

I hope this course can help you